Accessories

Accessories

Conveyor 22’s flexible building system simplifies installation and optimizes productivity.

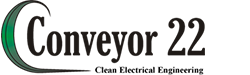

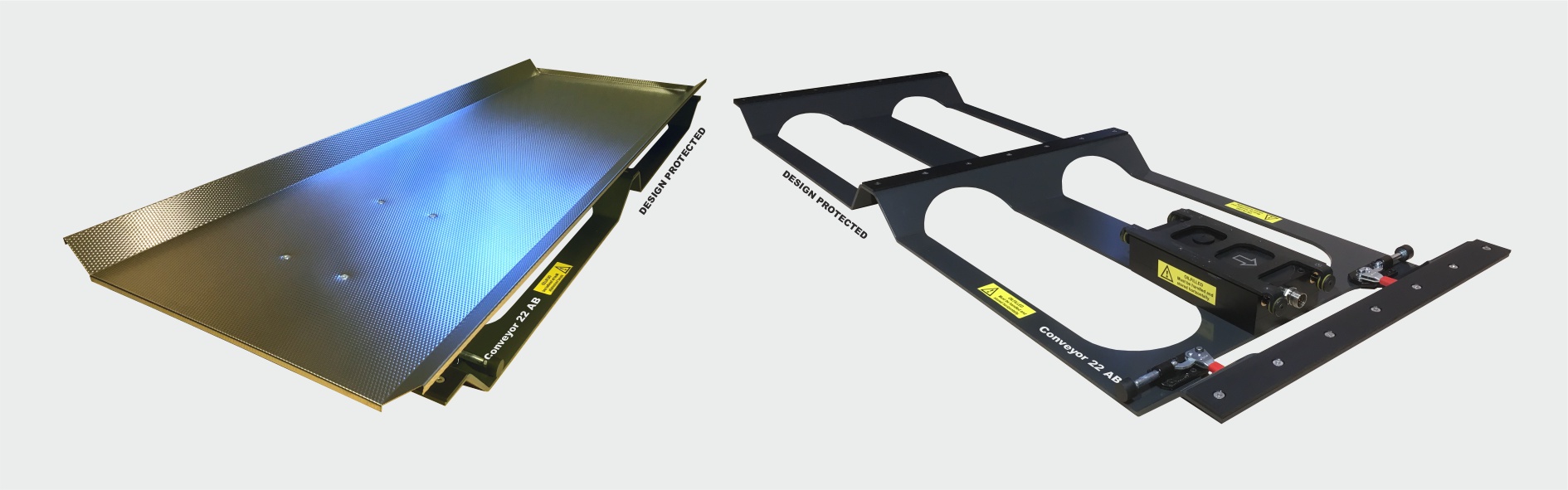

Aluminium bar

The low profile aluminium bar is string pressed and combines low weight and high strength. The broad profile with its twin T-slots is very stiff and stable giving very good torsional rigidity and stability. The anodized surface has a high surface finish and corrosion resistance. Multiple feeding trays can be mounted on the bar.

The bar can be delivered to you at all length scales.

Height: 16 mm

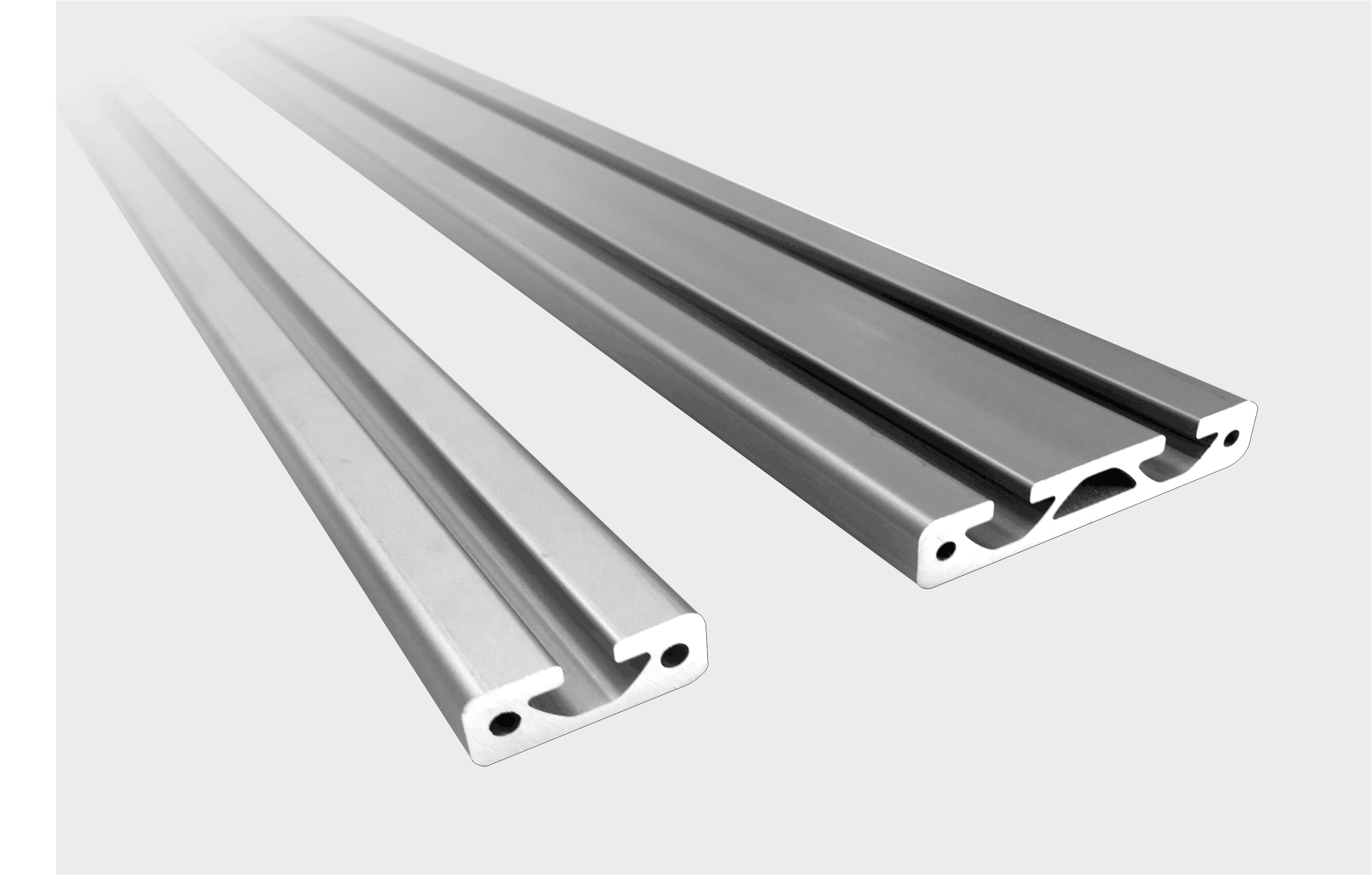

Quick Bar 1000 / 1500 / 2000

This flexible bar is designed for instant changing of multiple feeding trays. Easily mounted on the conveyor with Quick Bars integrated screws. Mechanical hand-tensioner locks in seconds the feeding tray in the Quick Bar tracks without tools.

Simplified handling – Shorter set-up time!

Height: 34 mm

Width: 83 mm

Weight: 1000 mm, 1500 mm or 2000 mm

Attachments of the conveyor

Conveyor Lift 200/278

Adjustable lift in height (Z), is specially designed for Black Line 101 & 121 conveyor. The lift can easily be mounted on the stamping press or manufacturing equipment with 4 x M12 bolts. In a few seconds, the height setting is easily done with a crank. The stroke level is 200 mm. When replacing manufacturing equipment, the conveyor bolted to the lift can be cranked down below the stamping press table’s surface.

Tool change is simplified – setup time is shortened!

Conveyor Lift 230/1100

Adjustable lift in height (Z), is specially designed for Black Line 101 & 121 conveyor. The lift can easily be mounted on the stamping press or manufacturing equipment with 4 x M12 bolts. In a few seconds, the height setting is easily done with a crank. The stroke level is 230 mm. The Conveyor lift 230/1100 is able to handle either Quick Bar 2000 mm or aluminium bar up to 3000 mm. When replacing manufacturing equipment, the conveyor bolted to the lift can be cranked down below the stamping press table’s surface.

Tool change is simplified – setup time is shortened!

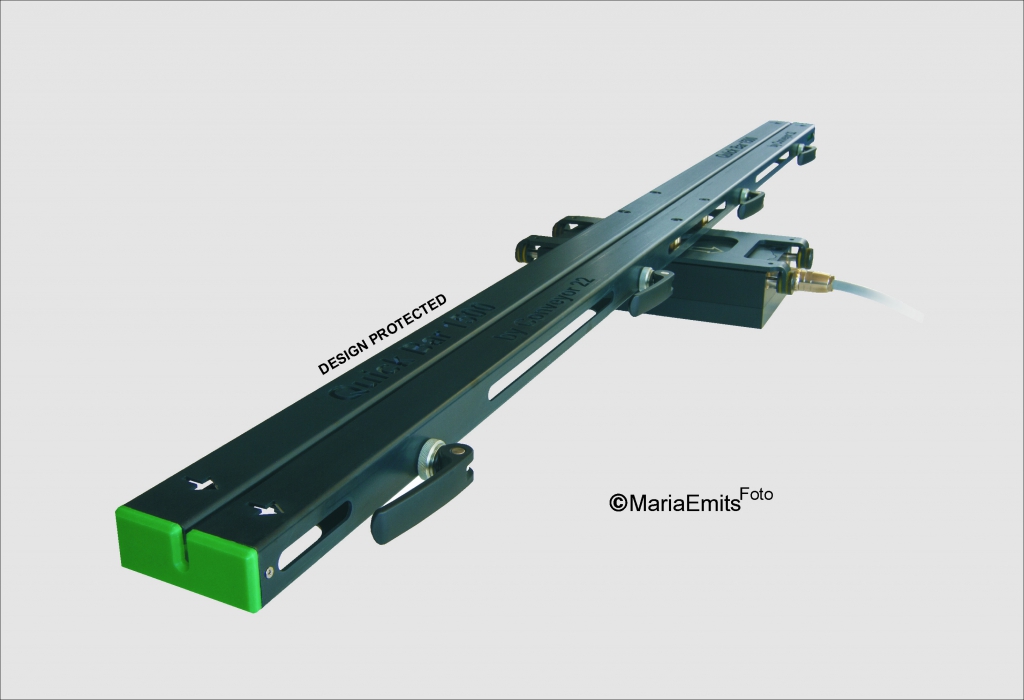

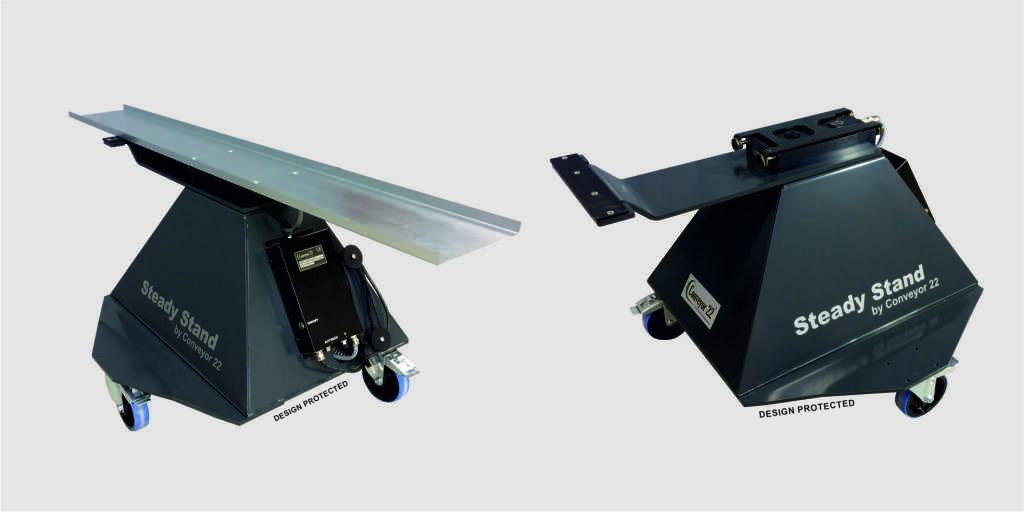

Steady Stand

Floor based stand is either fitted with machine feet or wheels with brakes, manufactured in high strength steel and customized in height.

Steady Stand is designed to enable the complete conveyor unit to be easily moved between different manufacturing machines. As an alternative to mounting the conveyor on a manufacturing machine, the Steady Stand is suitable to be an attachment to fasten the conveyor upon with feeding trays and other extra features.

Example: Steady Stand 500 – a low model, placed under the press table. 3-wheel adapter ensures the stability on uneven surfaces. The control box is mounted directly on Steady Stand and the cable between conveyor and control box is stored within the stand. Steady Stand 500 is cement-filled and weights 150 kg.

Tray support gives the feeding tray maximum stability. It comes with sliding elements in high molecular polyethylene, and is easily fitted under the conveyor with the same bolts as the conveyor is mounted with.

Material thickness: 10 mm

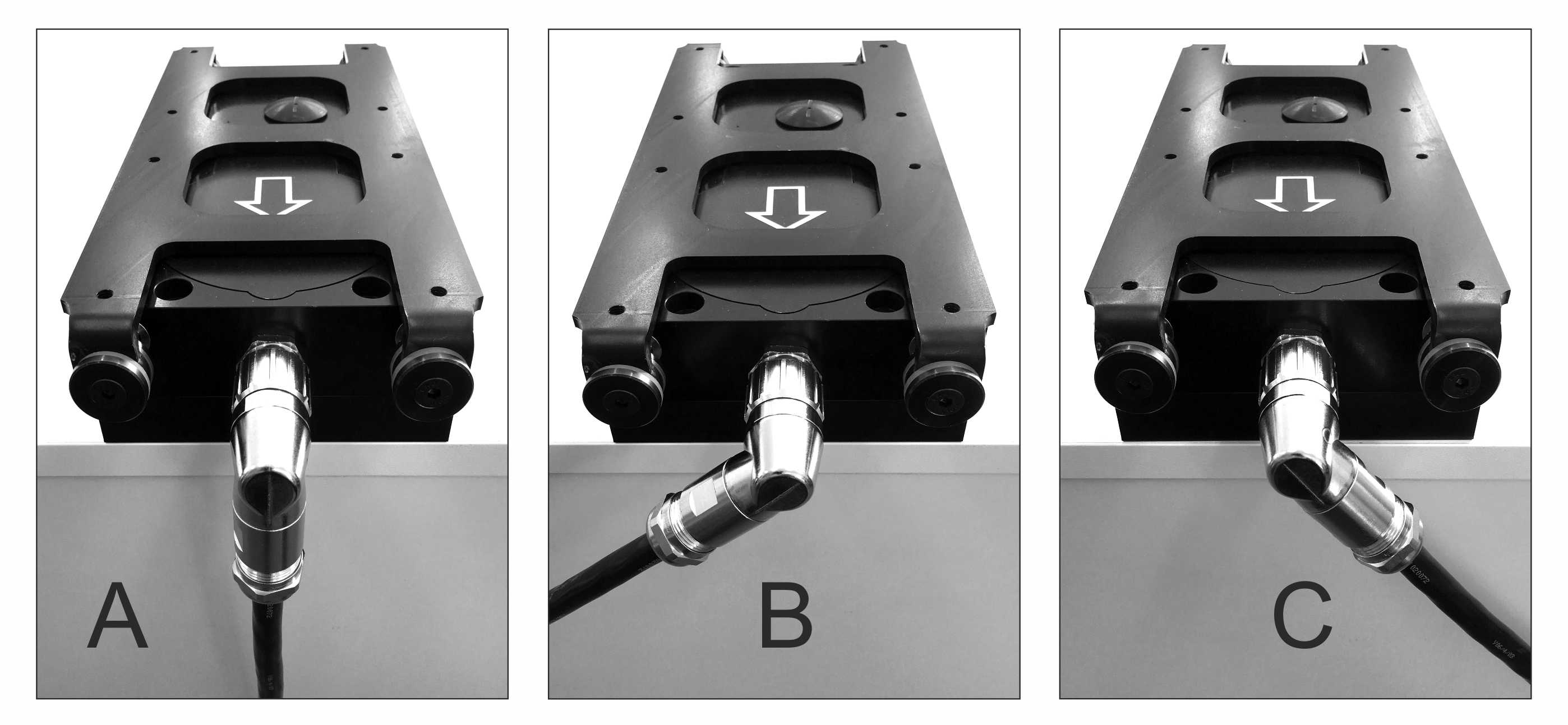

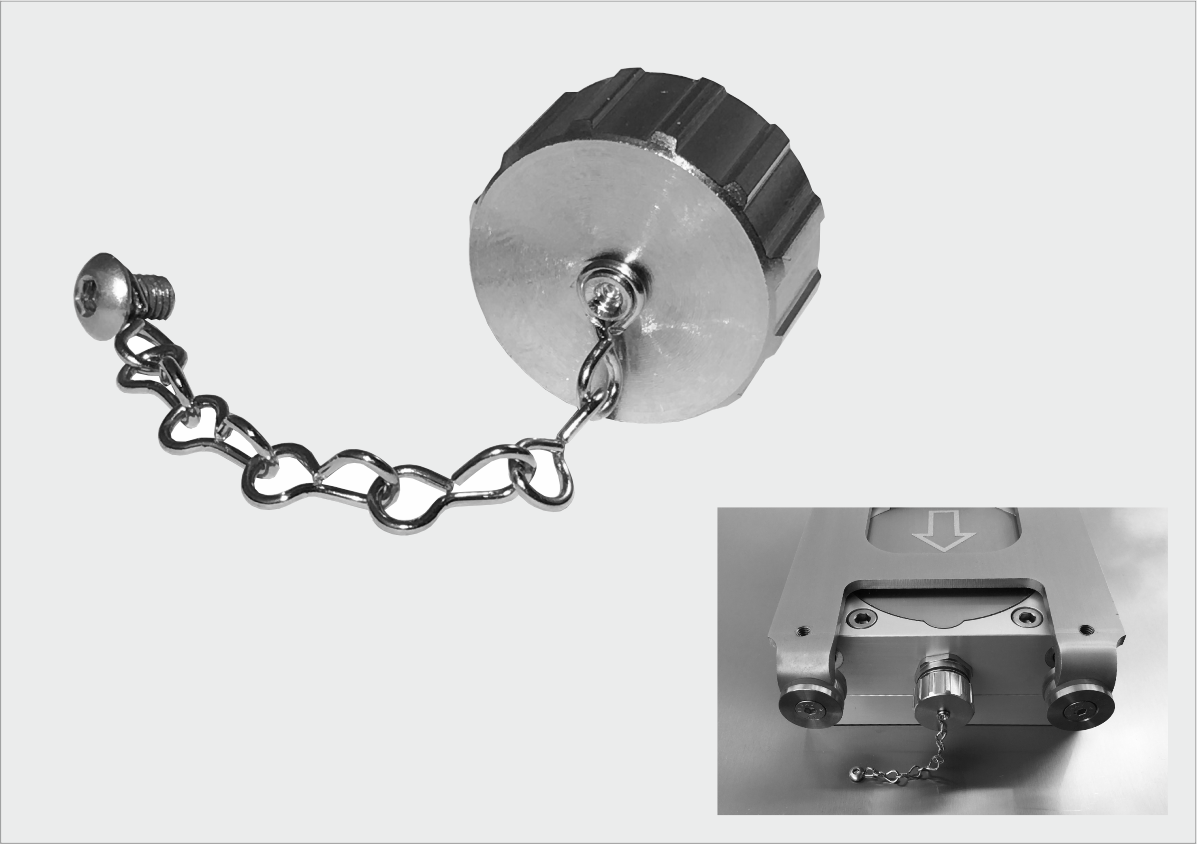

Quick Cassette

Quick Cassette is designed to easily insert the complete conveyor unit into various manufacturing machines. For example, it can be pushed in or under a stamping tool and locked in a few seconds. With the double hand tensioners, the whole conveyor unit is stably locked in the tool. Quick Cassette is available in different versions for Black Line 101 & 121 with three different options on width.

Material: high strength steel

Insert fastener for conveyor and feeding tray

Save Space – Reduce Setup Time

Turn Plate 90˚

Adjustable turn plate for Black Line 101 & 121 electric transporter.

Turn Plate 90˚ is smoothly adjusted with 45 degrees rotation of the conveyor to the right from neutral position and 45 degrees to the left from the neutral position. The turn plate is mounted with the supplied bolts and is locked with steel levers. Turn Plate 90 is manufactured in high strength steel.

Safety and control

M12 Signal Cable

The signal cable connects the control box and the stamping press/manufacturing machine.

The conveyor can easily be controlled remotely via cable. The control box also sends a signal through the signal cable to the stamping press/manufacturing machine in case of malfunction.

Length: 3000 mm

Warning Lamp Downtime

Warning lamp which lights up when the conveyor is overloaded – a cost efficient safety accessory

The warning lamp is a simple but important safety accessory that prevents downtime for those who choose not to connect the conveyor’s control box to the PLC.

If the conveyor is overloaded or stops for any reason, the high-intensity LED lights up and provides a clear and distinct visual warning. The warning lamp is placed clearly visible to the operator. Costly downtime and broken tools can thus be avoided.

The warning lamp is supplied with an M12 standard cable 3 meters which connects to the control box and is easily mounted with two included screws.

The warning lamp fits all our conveyors and is ready for our new potential-free control system. Then, the included 24VDC adapter shall be used.

Length: 3000 mm

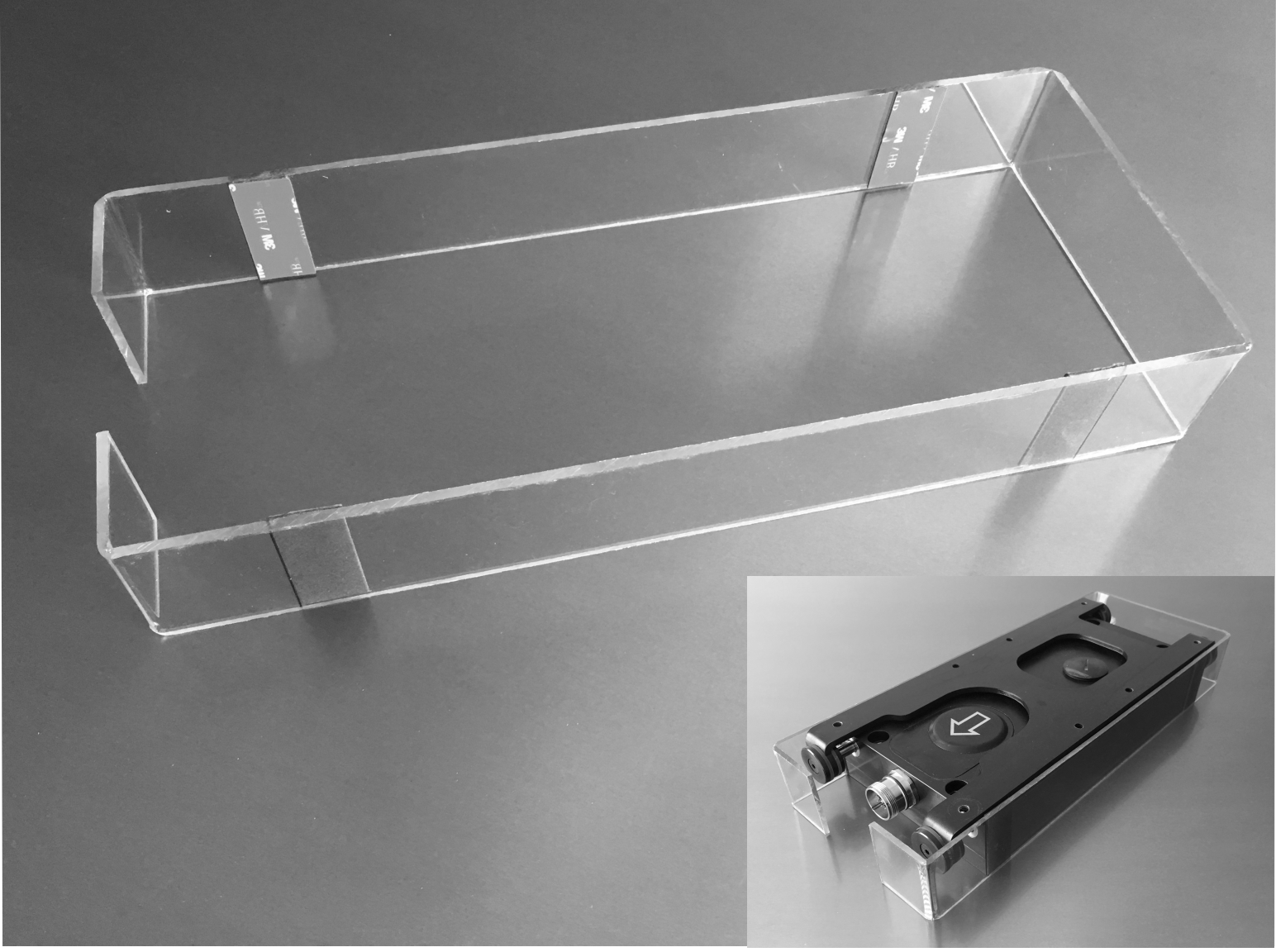

Anti-Pinch Barrier Side

Barrier is to reduce pinching risk when the conveyor is mounted unprotected, e.g. outside the manufacturing machine.

Made of 3 mm polycarbonate and comes with double-sided metal tape.

Dimensions for Model 101(LxWxH): 347x154x75 mm

Dimensions for Model 121(LxWxH): 346x146x67 mm

Dimensions for Model 141(LxWxH): 336x136x46 mm

Dimensions for Model 181(LxWxH): 306x126x35 mm

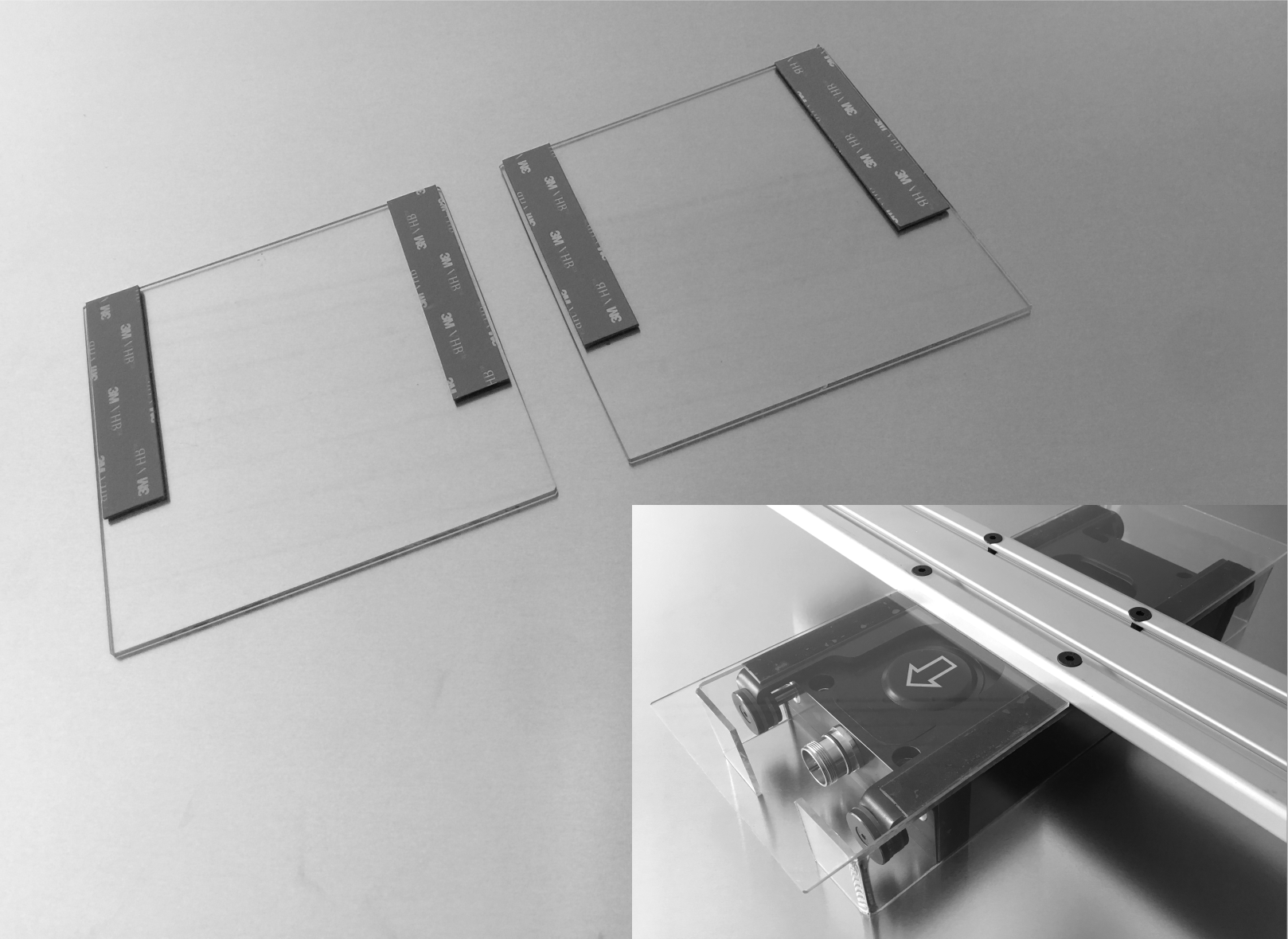

Anti-Pinch Barrier Top

Barrier is to reduce pinching risk when the conveyor is mounted unprotected, e.g. outside the manufacturing machine.

Made of 3 mm polycarbonate and comes with double-sided metal tape.

Dimensions for Model 101(LxWxH): 150x146x3 mm

Dimensions for Model 121 & 141(LxWxH): 150x138x3 mm

Dimensions for Model 181(LxWxH): 140x118x3 mm